Pushing nanomaterials up to the kilogram scale – An accelerated approach for synthesizing antimicrobial ZnO with high shear reactors, machine learning and high-throughput analysis

Abstract

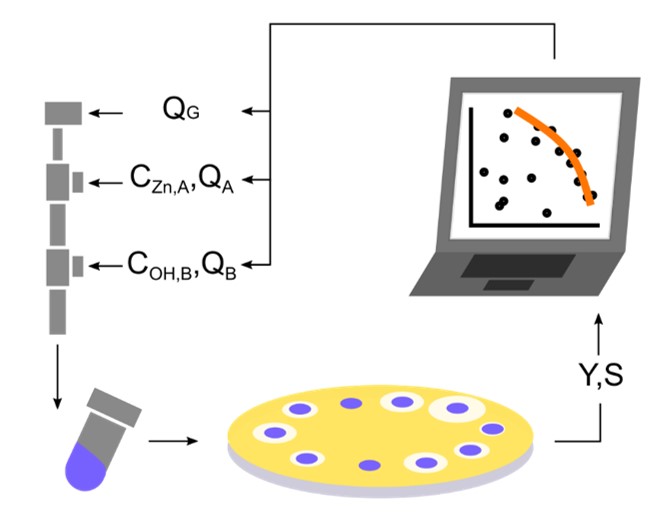

Novel materials are the backbone of major technological advances. However, the development and wide-scale introduction of new materials, such as nanomaterials, is limited by three main factors—the expense of experiments, inefficiency of synthesis methods and complexity of scale-up. Reaching the kilogram scale is a hurdle that takes years of effort for many nanomaterials. We introduce an improved methodology for materials development, combining state-of-the-art techniques—multi-objective machine learning optimization, high yield microreactors and high throughput analysis. We demonstrate this approach through the optimization of ZnO nanoparticle synthesis, simultaneously targeting high yield and high antibacterial activity. In fewer than 100 experiments, we developed a 1 kg day−1 continuous synthesis for ZnO (with a space-time-yield of 62.4 kg day−1 m−3), having an antibacterial activity comparable to hydrothermally synthesized nano-ZnO and cetrimonium bromide. Following this, we provide insights into the mechanistic factors underlying the performance-yield tradeoffs of synthesis and highlight the need for benchmarking machine learning models with traditional chemical engineering methods. Methods for increasing model accuracy at steep pareto fronts, in this case at yields close to 1 kg per day, should also be improved. To project the next steps for process scale-up and the potential advantages of this methodology, we conduct a scalability analysis in comparison to conventional batch production methods, in which there is a significant reduction in degrees of freedom. The proposed method has the potential to significantly reduce experimental costs, increase process efficiency and enhance material performance, which culminate to form a new pathway for materials discovery.